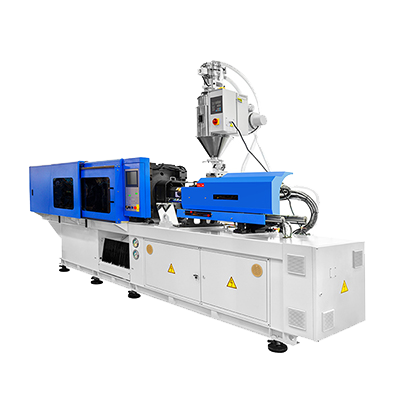

Injection Mold Tooling & Parts

Molding Full-Service Capabilities

Injection Molded Parts

- Exterior

- Interior

- Under-hood

- High-Voltage Connectors

Injection Mold Tooling

-

Complex Tools

-

Large Press (1000-3000T)

-

Small & Med Press

Tool Integration

-

2nd Stage Support

-

Repairs, Trials

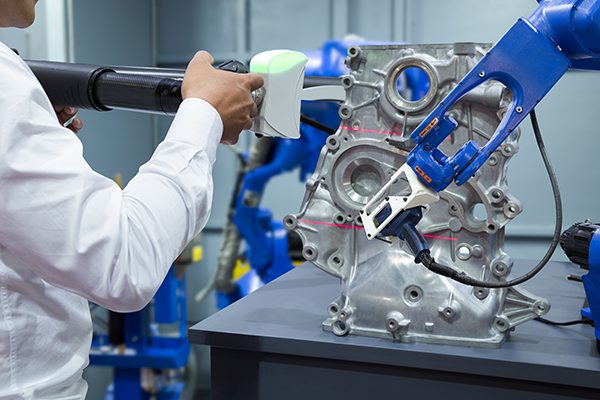

Technology

- In-line smart technology

- Robotics / End of Arm Tooling

- In-line vision system

- Kistler CPS Process Monitoring

Product & Molding

- Extensive knowledge of performance plastics

- Support customer with design and molding best practices

R&D

- Processes

- Materials

- Products

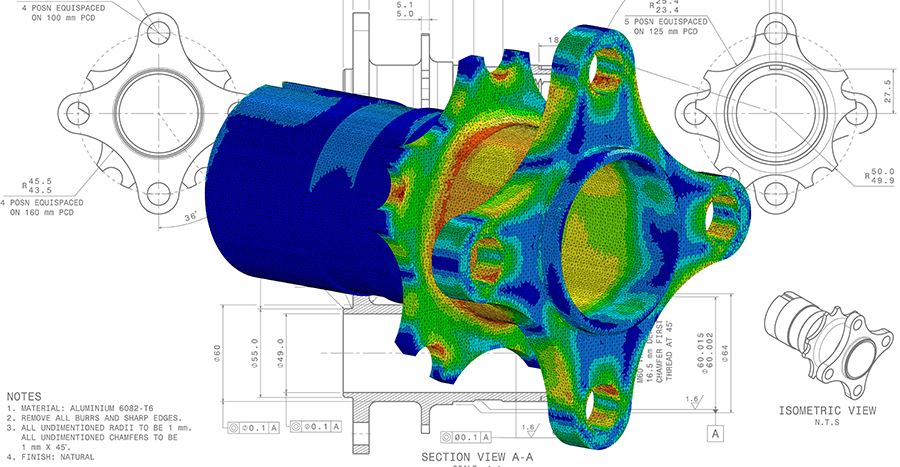

Design

- CAD - NX/Catia

- PLM

- FEA

- CFD

- On-site Designers

Tooling Manufacturing

- Molds

- Trimming Fixtures

- Assembly Cells

- Leak Testing

- QC Gages

Development

- Resin Selection

- FEA Analysis

- Mold Flow Analysis

- FMEA and DVP&R Development

Injection Molding

- 50T to 2000T

- Gas-Assist

- 2-Color

Decorating

- Paint

- Hot Stamp

- Pad Printing

- In-Mold Labeling

Assembly

- Robotized

- Inspection

- Hot Plate Welding

- Spin Welding

- Vibration Welding

- Prototype Samples